Home | Construction

1 | Construction 2 | Construction

3 | Shopping

List | PC & Configuration | Graphics & Plans

Day 1:

08:00

|

|

We had already bought

the wood, three sheets of MDF measuring 8 foot by 4 foot each.

WIth the exception of a few small bits we found lying around

the garage, everything was purchased for the construction project.

You can find the 'Shopping List' from the links above.

The plans for the cabinet

were loosely based upon LuSID's

work, but with modifications to the dimensions and control

panel. As we weren't using the same wood thickness as was mentioned

in the plan it really just served as a guide to ensure that the

machine looked correct once assembled. Everything else we kind

of made up as we went along. |

|

|

|

Due to bad weather

during the first part of construction we had no power,

so we began by hand sawing the shape |

|

| Careful measurements,

and some rough pencil sketches on the wood served as the

guides |

|

|

|

|

| Rather than LuSID's

huge control panel, we wanted something a bit more subtle.

We also decided to angle the base of the control panel

back in to make the base of the cabinet narrower. This

looked better and didn't take up quite as much room as

the original plans showed. |

|

Of

course you need two sides - so simply lay the first side

on a new piece of MDF and draw carefully round it. At this

point without the power tools we couldn't quite cut the

screen edge correctly as it was tricky to get the handsaw

in, and needed a curve to the top marquee unit.

Note

in the pictures above, you're looking at the cabinet

upside down - the bit sticking out at the base will actually

be at the top of the cabinet

|

|

Day

1: 09:16

|

|

|

| Just to recap

- this is where we are: One roughly cut side of the cabinet

- and a lot of uncut wood. |

|

The

next thing to do was to finish the first side - mark the

outline on a fresh sheet of MDF, and then cut the second

side out.

This

is much easier with a power saw (the power came back).

|

|

Day 1: 09:49

|

|

|

Once

the left and right sides were cut, it was time to cut

the piece for the bottom. We took rough dimensions from

LuSID's plans, modified to whatever the size was of the

edges that we'd already cut.

|

|

To

go along with the bottom, we needed a top. This would then

make the cabinet free-standing so we could measure and

cut some of the other panel pieces.

|

|

|

|

|

To

hold everything together we used battens added to

the inside of the frame onto which we screwed the

other pieces.

|

|

We

screwed them from the outside, countersinking the screw-heads

to allow them to be filled and, ultimately, painted over.

|

|

|

|

|

You

can see the two screws in place here

|

|

You

can see the batten screwed onto the outside. Yes, the screws

were too long, but we had already bought 400 of them.

|

|

Day 1: 10:57

|

|

|

You can now

see most of the battens in place on one of the sides.

Two useful tools are resting on the surface - a block

that allowed you to scribe the edge of the frame exactly

9mm

(the

width of the MDF) from the edge - and a small piece

of MDF to check the position before the battens were screwed

in.

In the end

(and much later in construction) for additional stability,

we took all the battens off - glued them - and reassembled

them. If you're sure about what you are doing, you

may as well glue them as you go.

|

|

Here

is the edge piece with all its battens in place.

|

|

|

|

|

A

close-up of the back edge

|

|

And

one of the control panel housing.

|

|

Day 1: 11:39

|

|

|

Once

we'd put the battens on both sides, it was possible to

assemble some portions so the cabinet would stand.

|

|

The

cabinet is laying on its back here.

|

|

|

|

|

Still

laying on its back, looking at the top and down to the

control panel housing.

|

|

Another

angle - just so you can get the feel for the construction.

|

|

Day 1: 11:50

|

|

|

The

first picture of it standing up under its own power!

|

|

The

same view from the back. Not too bad for just over two

hours work

|

|

Day 1: 11:55

|

|

|

It

was now time for the control panel. We cut a piece of

wood to fit the gap and took careful measurements.

|

|

It's

probably a good time to introduce my controls. I chose

to connect the controls to the PC using an I-PAC from Ultimarc.

Whilst I was about it, I got two J-Stiks - a collection

of buttons and a crimping tool.

|

|

|

|

|

A

couple of the 20 buttons I ordered (which match the inputs

available on the I-PAC).

|

|

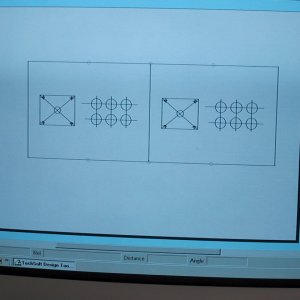

We

programmed the measurements of all the controls, and of

the control panel board into a CAD package which made it

easy to sort out alignment design. Having decided to go

with just the two sticks and six-player buttons on the

main control panel all we had to do was click 'print'

|

|

Day 1: 12:56

|

|

|

With

the paper in hand, we glued it to the top of the control

panel, making sure to centre it along both axis.

|

|

With

the centres of the holes marked out on the CAD package,

we centre-punched each button to enable our big hole-cutting-drill

to get started.

|

|

|

|

|

We

drilled each of the twelve button holes from both sides

to make sure that the edges were as smooth as could be.

|

|

A

quick rub over with glass paper and the panel was ready

for wiring.

When

the cabinet is finally decorated there will probably

be some perspex over the control panel to give it some

extra toughness.

|

|

Day 1: 13:29

|

|

|

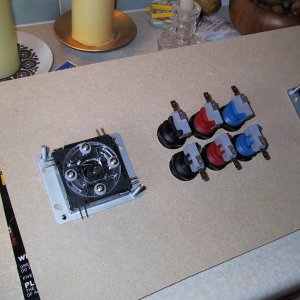

First

the controls were screwed into the panel - taking care

to match the button colours for player one and player

two of course!

|

|

These

were the other things that were going to be needed - wire,

a crimping tool and the I-PAC interface board.

|

|

|

|

|

A

quick turn-over to make sure that everything looked okay.

|

|

And

then installation of the micro-switches in each of the

buttons.

|

|

|

|

|

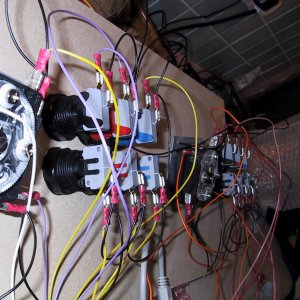

The

wiring was fairly simple - a common line running around

all the controls, then each control individually wired

to the I-PAC. As there were eight more buttons that were

going into the cabinet I just left then trailing for

now whilst I decided where they went (and left plenty

of cable!)

|

|

More

detail of the wired-up controls.

The

gray wire at the bottom of the picture goes to the PC

which was on the floor - I thought it was probably a

good time to give the controls a test. Worked first time

...

|

|

Home | Construction

1 | Construction 2 | Construction

3 | Shopping List | PC & Configuration | Graphics & Plans

|